In heavy-duty vehicles and some older cars, the brake drum is an indispensable component of the braking system. It works in conjunction with brake shoes to convert the vehicle's kinetic energy into heat through friction, enabling deceleration or stopping. The reliability and durability of this braking system make it still very popular in specific applications.

Internal Structure of the Brake Drum

While a drum brake may seem simple, its interior is composed of several precise components, each playing a crucial role.

-

Brake Drum: This is the outer shell of the braking system, typically made of cast iron and shaped like a bowl. It rotates with the wheel and is the direct object of friction for the brake shoes. It is sometimes also referred to as a brake housing or drum shell.

-

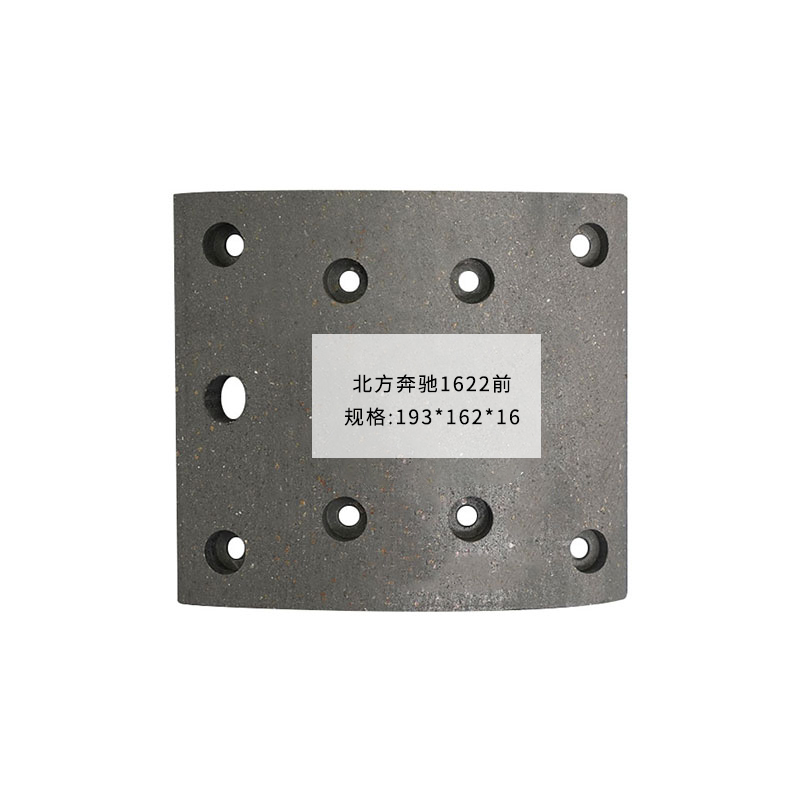

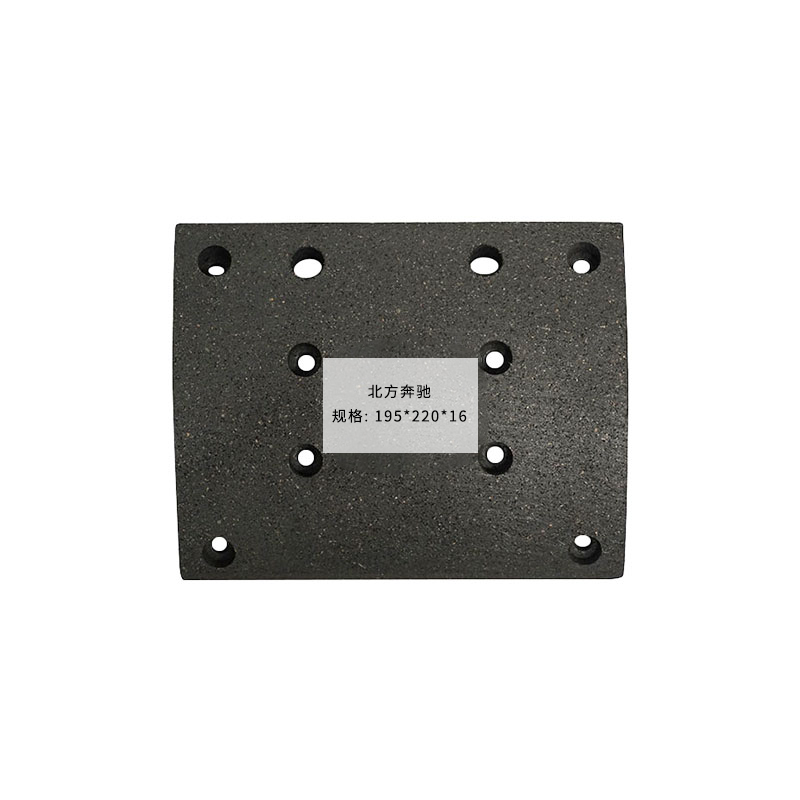

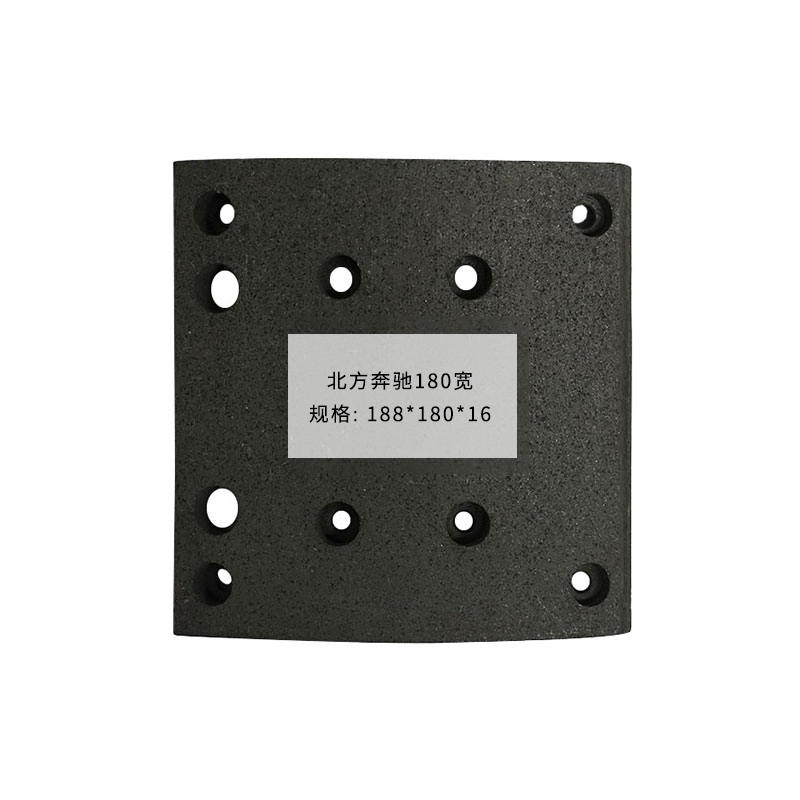

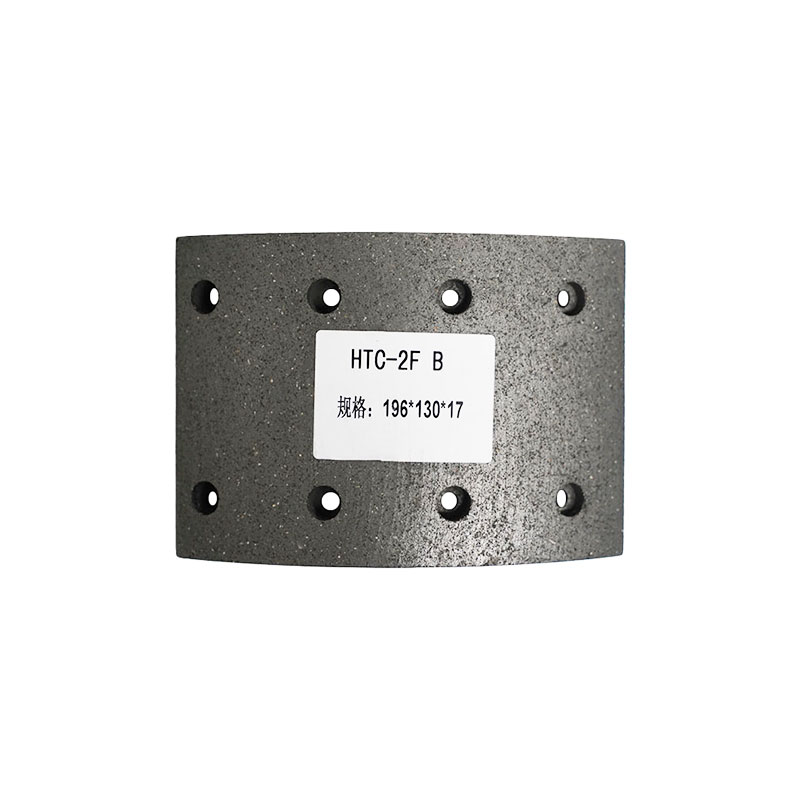

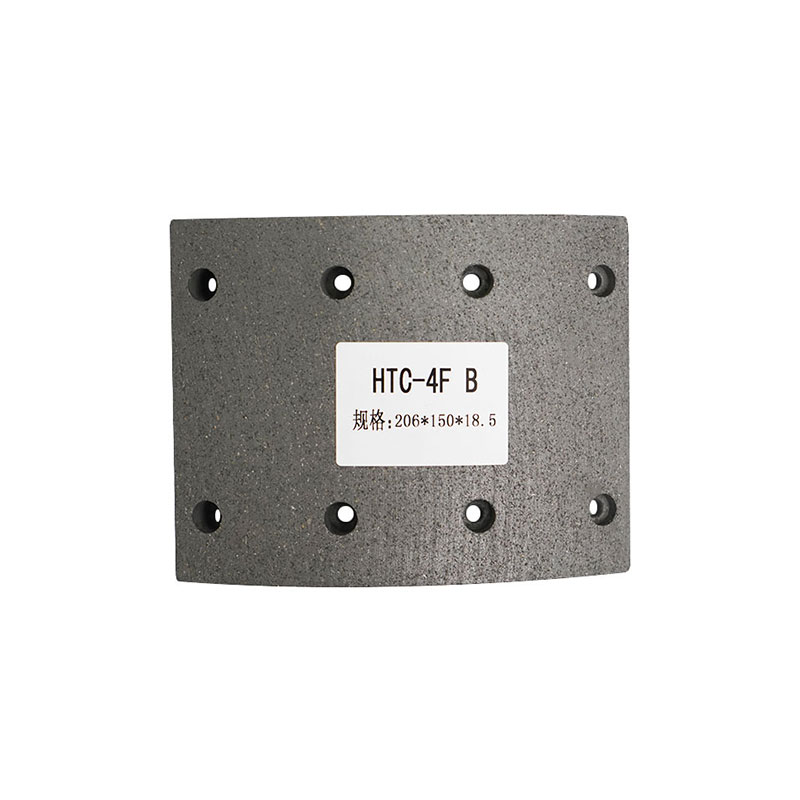

Brake Shoes: Two crescent-shaped parts, usually consisting of a steel frame and a friction lining. When the driver presses the brake pedal, the brake shoes are pushed against the inner wall of the brake drum by a hydraulic or mechanical device, creating friction.

-

Wheel Cylinder: This is the hydraulic actuator within the drum brake system. When brake fluid flows from the master cylinder to the wheel cylinder, it pushes pistons inside the cylinder, which in turn push the brake shoes outward. In some mechanical braking systems, this function is performed by rods or cams.

-

Return Springs: These strong springs are connected between the brake shoes. When the driver releases the brake pedal, the return springs pull the brake shoes back to their original position, disengaging them from the inner wall of the brake drum and releasing the brake.

-

Self-adjuster: As the brake shoes wear down, the gap between the brake drum and shoes increases. The self-adjuster automatically adjusts the position of the brake shoes to ensure the gap remains optimal for effective braking.

How It Works

The brake drum operates on the principle of friction. When the driver presses the brake pedal, the hydraulic master cylinder pushes brake fluid to the wheel cylinders at each wheel. Inside the brake drum, the pistons in the wheel cylinder are pushed, forcing the brake shoes outward. The friction material on the brake shoes contacts the inner wall of the rotating brake drum, generating powerful friction. This friction applies a braking torque to the wheel, slowing it down. When the pedal is released, the brake fluid pressure is released, the return springs pull the brake shoes back, and the braking process ends.

Pros and Cons

Pros:

-

Lower Cost: Compared to disc brakes, brake drums are generally less expensive to manufacture.

-

Self-Actuating Effect (Servo action): When the brake shoes contact the rotating brake drum, the friction generates an additional force that further pushes the shoes against the drum wall, enhancing braking power, which is particularly effective in heavy-duty vehicles.

-

Handbrake Integration: The handbrake system can be easily integrated inside the brake drum, simplifying the mechanical structure.

Cons:

-

Poor Heat Dissipation: The heat from the brake drum is primarily dissipated through its outer shell, but due to its enclosed structure, the heat dissipation efficiency is much lower than that of disc brakes. This can lead to brake fade during continuous braking or on long downhill slopes.

-

Inconvenient Maintenance: To replace brake shoes or perform maintenance, the entire brake drum must be removed, which is a relatively cumbersome operation.

-

Slower Response: Due to the need to overcome the tension of the return springs, the response time of a drum brake is typically slightly slower than a disc brake.

Despite these drawbacks, the drum brake system remains important in certain applications like rear wheel braking, handbrake systems, and heavy-duty trucks and buses, thanks to its durability and cost-effectiveness. While new braking technologies continue to emerge, understanding the classic principle of the brake drum is essential for a comprehensive grasp of automotive braking technology.

English

English 中文简体

中文简体