The roar of an engine, the sleek curves of a chassis—these are the things that capture our imagination when we think about cars. But what about the quiet efficiency of the braking system? The ability to stop a vehicle is just as crucial as the power to make it go. At the heart of this critical process lies the Automobile Brake Lining, a component that performs the most essential of all automotive functions: converting motion into a standstill.

The Brake System Ecosystem: Where the Lining Fits In

To truly appreciate the Automobile Brake Lining, we must understand its role within the larger braking ecosystem. This isn't just a single part; it's a finely tuned assembly of interconnected components. When you press the brake pedal, you're initiating a hydraulic chain reaction.

-

The Pedal and Master Cylinder: Your foot's force on the pedal pushes a piston in the master cylinder.

-

Brake Fluid: This pressure is then transmitted through the incompressible brake fluid, traveling through a network of brake lines.

-

Wheel Cylinder: The pressurized fluid reaches the wheel cylinder, forcing its pistons to move outwards.

-

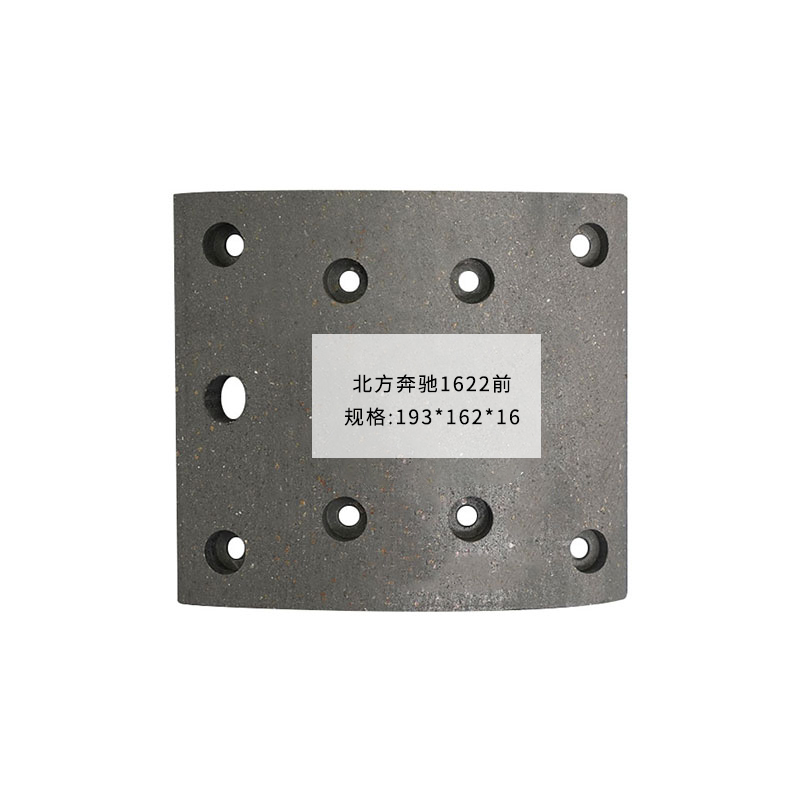

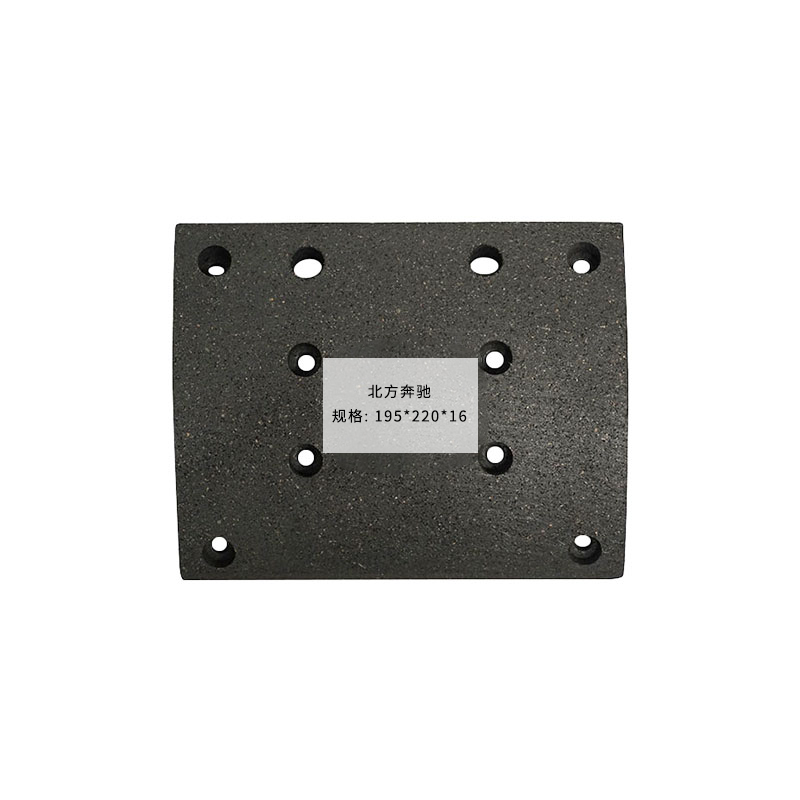

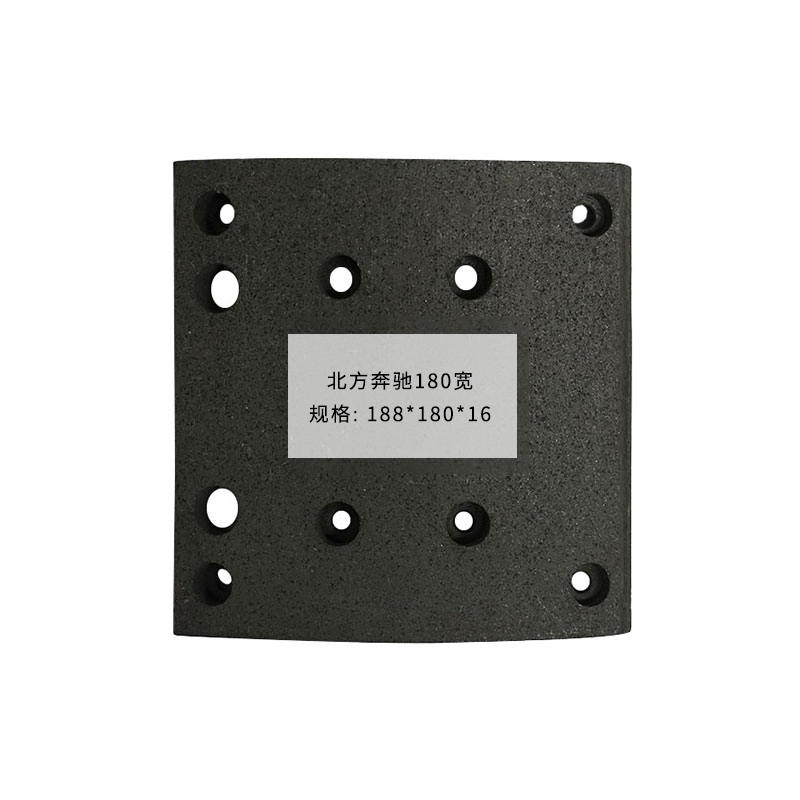

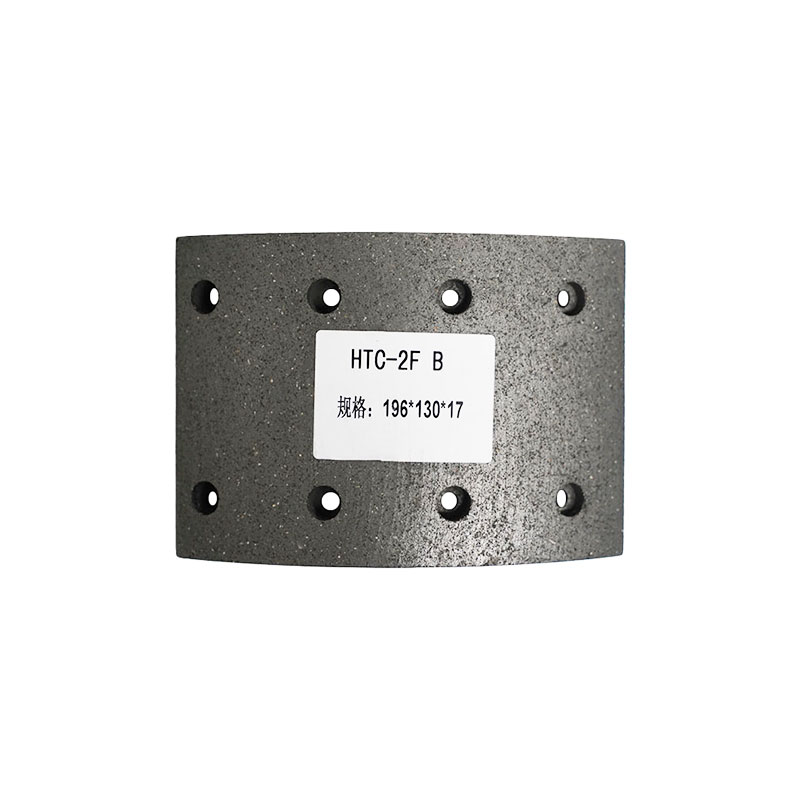

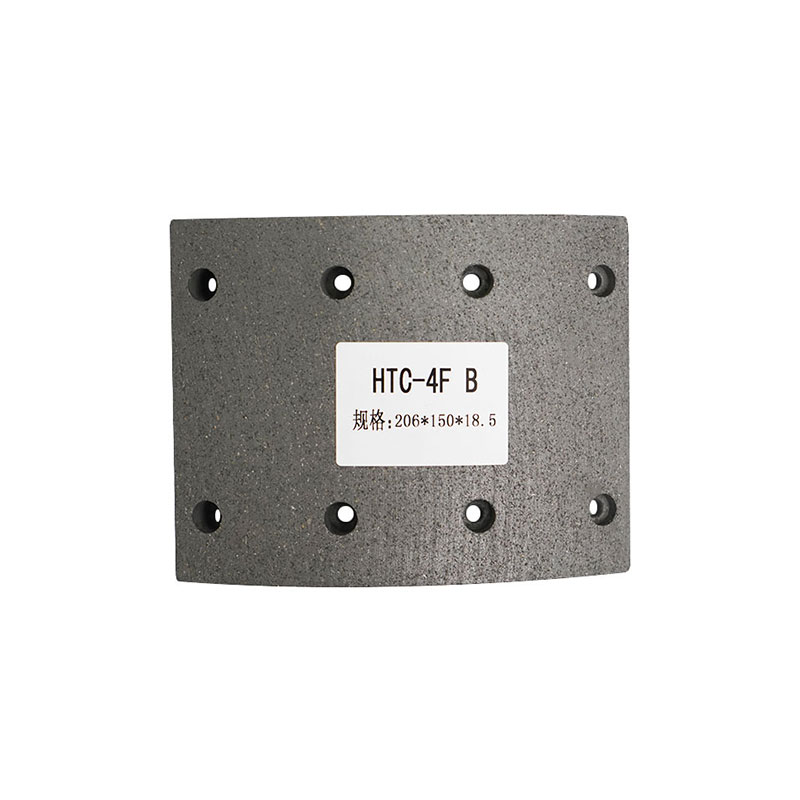

Brake Shoe and Lining: These pistons push the brake shoe—a curved metal piece—outward. Bonded to the shoe is the Automobile Brake Lining.

-

Brake Drum: The expanding shoe forces the lining to press against the inner surface of the rotating brake drum.

It is at this point that the magic happens. The friction between the lining and the drum transforms the car’s kinetic energy (the energy of motion) into thermal energy (heat), effectively slowing the wheel's rotation until the vehicle comes to a complete stop.

The Physics of Friction: The Key to Braking

The entire process relies on the fundamental principles of friction. There are two types at play here: static and kinetic friction. While a car is in motion, the friction between the Automobile Brake Lining and the drum is kinetic, or "sliding" friction. The amount of friction generated is directly proportional to the force applied to the brake pedal.

This is where the material composition of the lining becomes critical. A lining must possess a high "coefficient of friction"—a measurement of how much friction it can generate. However, it’s not as simple as making the lining as "grippy" as possible. The material also needs to be durable enough to withstand the immense heat generated during braking.

Imagine a sudden stop from high speed. The temperature of the brake lining can soar to hundreds of degrees Celsius in a matter of seconds. This heat can cause a phenomenon called "brake fade," where the friction coefficient drops significantly, and the brakes feel less effective. Modern brake linings, particularly ceramic and semi-metallic ones, are engineered to resist this heat build-up and maintain a consistent friction level, ensuring reliable performance even under extreme conditions.

The Evolution from Asbestos to High-Tech Composites

For decades, asbestos was the material of choice for Automobile Brake Lining because of its excellent heat resistance and low cost. However, the severe health risks associated with asbestos fibers led to a global ban and a revolution in material science.

This forced engineers to innovate, leading to the diverse range of materials we see today. The shift from asbestos to composites was a major engineering challenge. Scientists had to find new combinations of materials that could replicate asbestos's performance without its dangers. The result is a blend of fibers, fillers, and binders—a complex formula that is a carefully guarded secret for each manufacturer. The performance of these modern linings is a testament to the ingenuity of engineers who had to solve a complex problem under strict new safety requirements.

Why Quality Matters for Your Automobile Brake Lining

Given their crucial role, it's clear that not all brake linings are created equal. Using a cheap, low-quality lining is a false economy. An inferior Automobile Brake Lining may wear out faster, cause more damage to your brake drums, and, most importantly, provide inconsistent or reduced stopping power, putting you and others at risk.

Choosing a high-quality lining from a reputable brand ensures that the material has been rigorously tested to meet safety standards and perform reliably under various driving conditions. It’s an investment in your safety and the longevity of your vehicle’s braking system.

Ultimately, the Automobile Brake Lining is a prime example of how sophisticated engineering and material science work in harmony to make our daily lives safer. It may be out of sight and out of mind for most drivers, but its contribution to road safety is incalculable.

English

English 中文简体

中文简体