While the fundamental principle of friction remains constant, the demands placed on an Automobile Brake Lining vary dramatically depending on the vehicle it's installed in. The requirements for a compact car navigating city streets are vastly different from those of a heavy-duty truck descending a mountain pass. This highlights the incredible versatility and specialized engineering required for this seemingly simple component.

The Daily Grind: Brake Linings in Passenger Vehicles

For most of us, our experience with an Automobile Brake Lining is in a passenger car. Here, the primary concerns are quiet operation, minimal brake dust, and a long service life. The stop-and-go nature of urban driving and the moderate speeds of highway travel mean that the brakes are used frequently but not typically subjected to extreme heat.

This is why Non-Asbestos Organic (NAO) and Ceramic brake linings are so popular in this segment. NAO linings are a cost-effective choice that provides a quiet and smooth braking feel, perfect for the average commuter. Ceramic linings, while more expensive, are highly valued for their exceptional quietness and the fact that they produce very little dust, which helps keep expensive alloy wheels clean. For a family sedan or a small SUV, the focus is on comfort, durability, and a pleasant driving experience.

The Performance Challenge: Brake Linings in Sports Cars

When you step into the world of high-performance vehicles, the requirements for the Automobile Brake Lining change entirely. Here, the priority shifts from comfort to absolute stopping power and heat resistance. A sports car can generate an enormous amount of kinetic energy, and its brakes must be able to dissipate that energy quickly and repeatedly without suffering from brake fade.

This is where Semi-Metallic and specialized ceramic-carbon compound linings shine. Semi-metallic linings, with their high metal content, are masters at heat dissipation. They can handle the immense temperatures generated during hard braking on a racetrack or a spirited drive on a winding road. They provide a firm, confident pedal feel, giving the driver a direct connection to the car's stopping performance. While they can be a bit noisier and produce more dust, this is a trade-off that performance enthusiasts are more than willing to accept for superior stopping power.

Heavy-Duty Demands: Brake Linings in Trucks and Commercial Vehicles

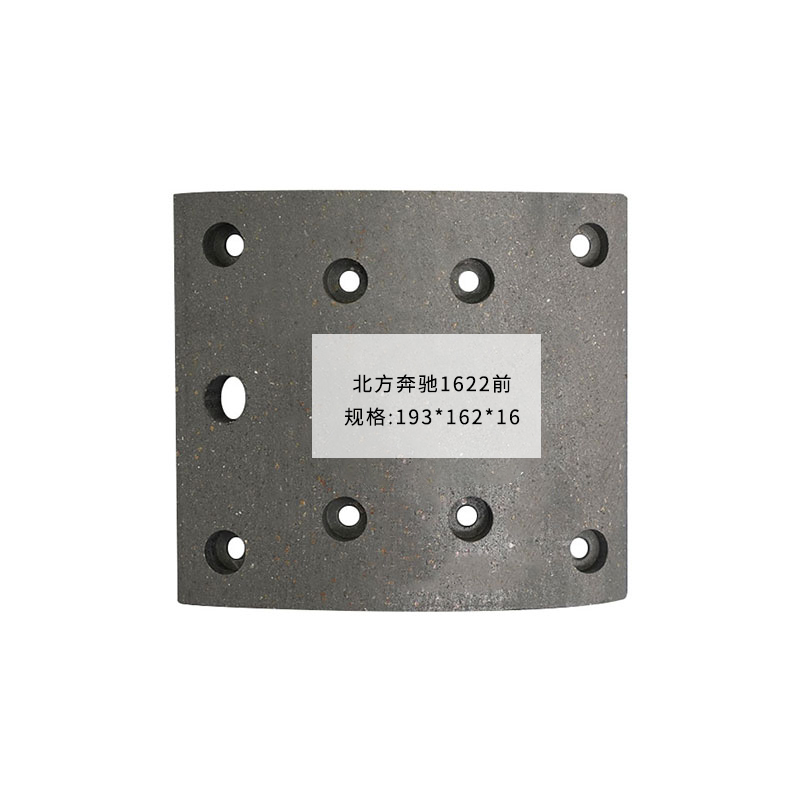

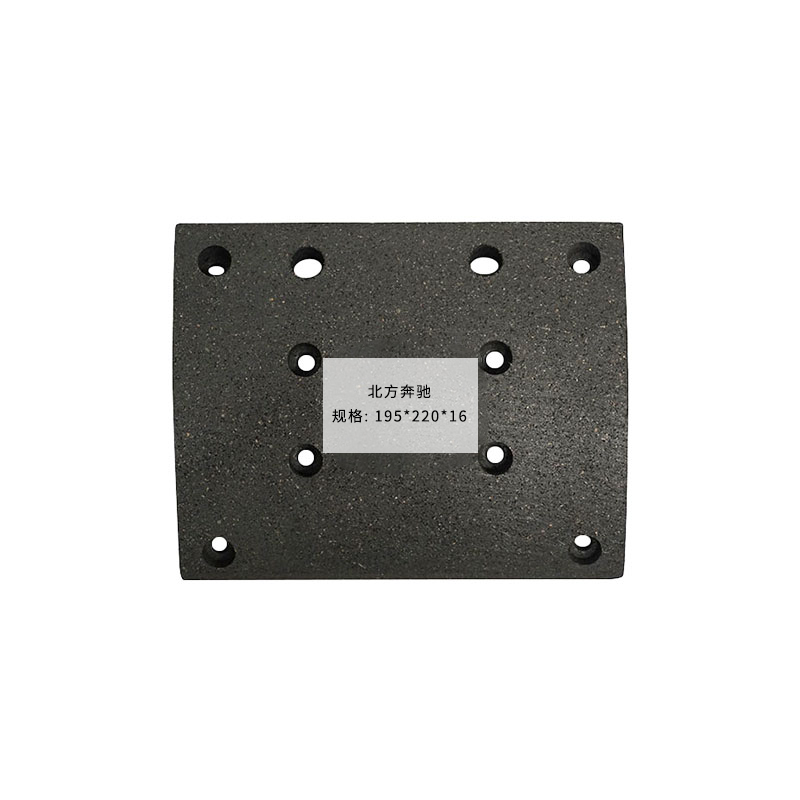

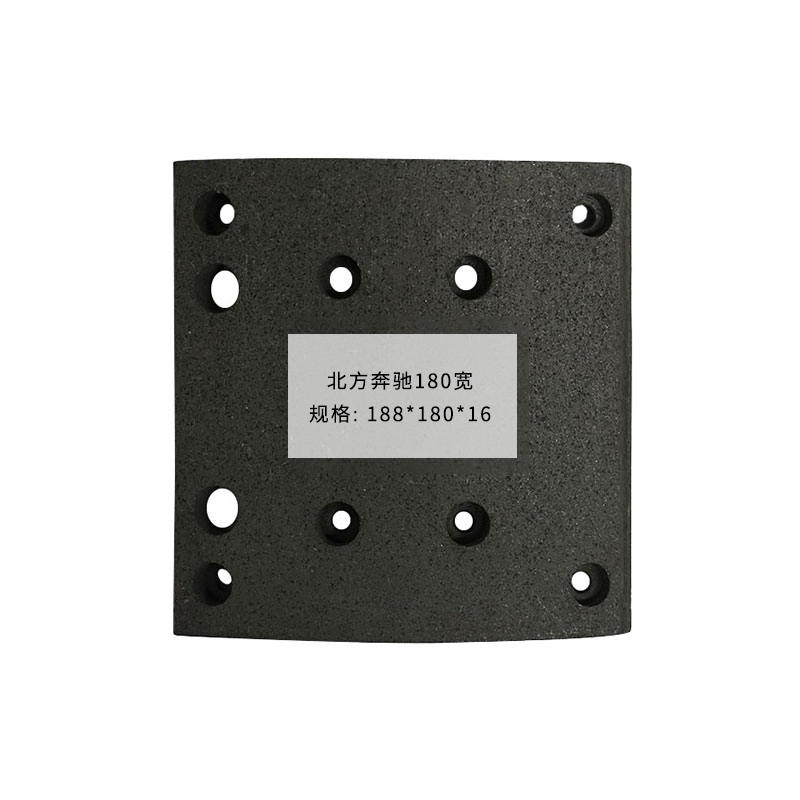

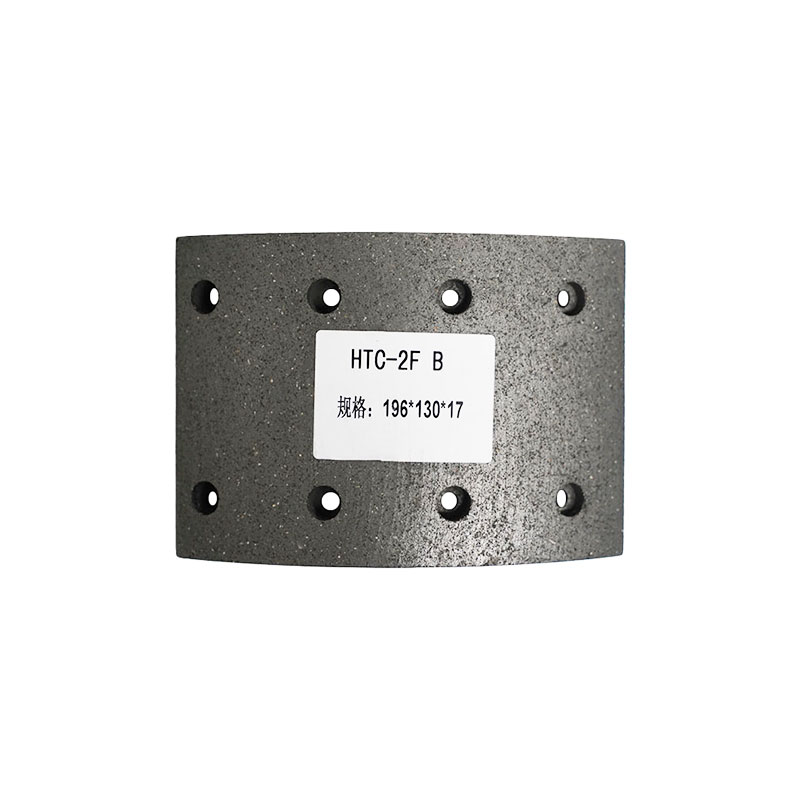

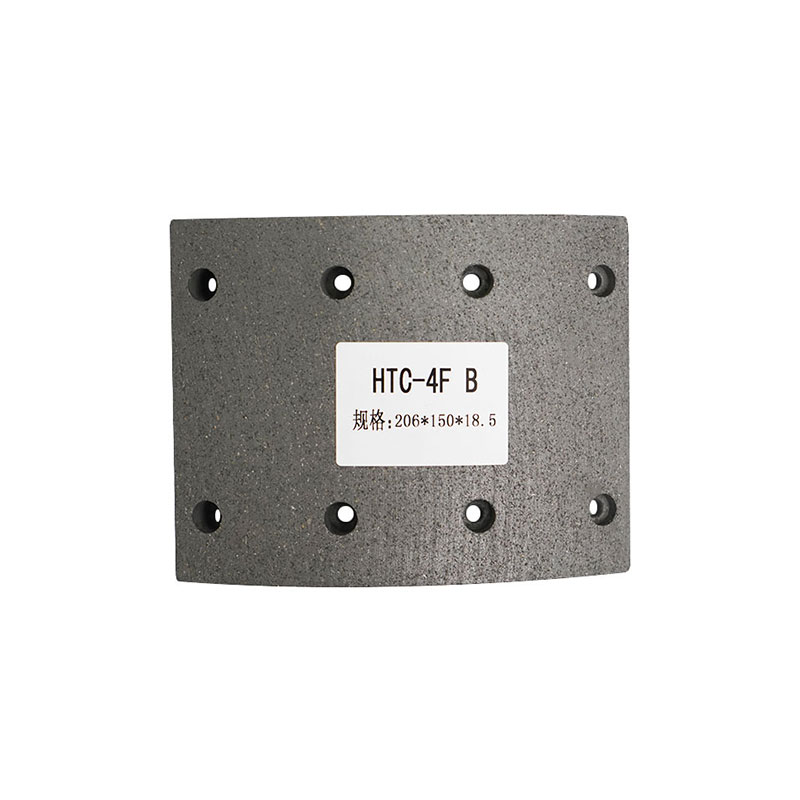

Perhaps the most challenging environment for an Automobile Brake Lining is a heavy-duty truck or a commercial vehicle. These vehicles carry immense loads and need to be able to stop safely under all conditions, often while on steep grades. The sheer mass of the vehicle and its cargo means that the brakes must absorb and dissipate a staggering amount of energy.

The linings used in these applications are engineered for extreme durability and heat resistance. They are often thicker and made from heavy-duty semi-metallic or organic materials with specific formulations to withstand prolonged braking events. For instance, the constant application of brakes while a truck descends a long hill can cause temperatures to skyrocket. This requires a lining that not only resists brake fade but also has a very long wear life to minimize downtime for maintenance. The reliability of the Automobile Brake Lining in these vehicles is not just a matter of convenience; it’s a critical factor in highway safety.

A Common Thread of Safety

Despite these differences, one thing remains constant across all applications: the Automobile Brake Lining is the single most important wear component for vehicle safety. Whether it's a small car carrying a family, a race car speeding around a track, or a truck carrying vital cargo, the lining must perform its job flawlessly. The material science behind these components is a continuous journey of innovation, always striving to improve performance, longevity, and safety for every type of vehicle on the road.

English

English 中文简体

中文简体