Understanding Brake Lining and Its Importance

Brake lining is a critical component of a vehicle’s braking system. It is the friction material attached to brake shoes or pads that presses against the brake drum or rotor to slow down or stop a vehicle. The performance of brake linings directly affects vehicle safety, stopping distance, and overall driving comfort. With technological advancements, modern brake linings are designed to balance durability, noise reduction, and environmental compliance.

Materials Used in Brake Lining

Brake linings are manufactured from a variety of materials depending on the intended application, vehicle type, and performance requirements. Common materials include:

- Asbestos-based linings: Once popular for their excellent heat resistance, now largely phased out due to health hazards.

- Non-asbestos organic (NAO) linings: Made from fibers, fillers, and binders; provide quieter operation but may wear faster.

- Semi-metallic linings: Contain metal fibers for improved heat dissipation and durability; ideal for heavy-duty vehicles.

- Ceramic linings: Offer low dust, quiet operation, and long lifespan; suitable for high-performance cars.

Key Performance Factors of Brake Linings

The effectiveness of brake linings is determined by several factors. Understanding these factors helps in selecting the right lining for different vehicles and driving conditions:

- Friction Coefficient: Determines the stopping power; must remain consistent across various temperatures.

- Wear Resistance: Affects the longevity of the lining; highly durable materials reduce maintenance costs.

- Heat Tolerance: High friction generates heat, so linings must resist thermal degradation.

- Noise and Vibration: Proper design reduces squealing and vibrations during braking.

- Environmental Impact: Modern linings aim to minimize harmful materials and dust emissions.

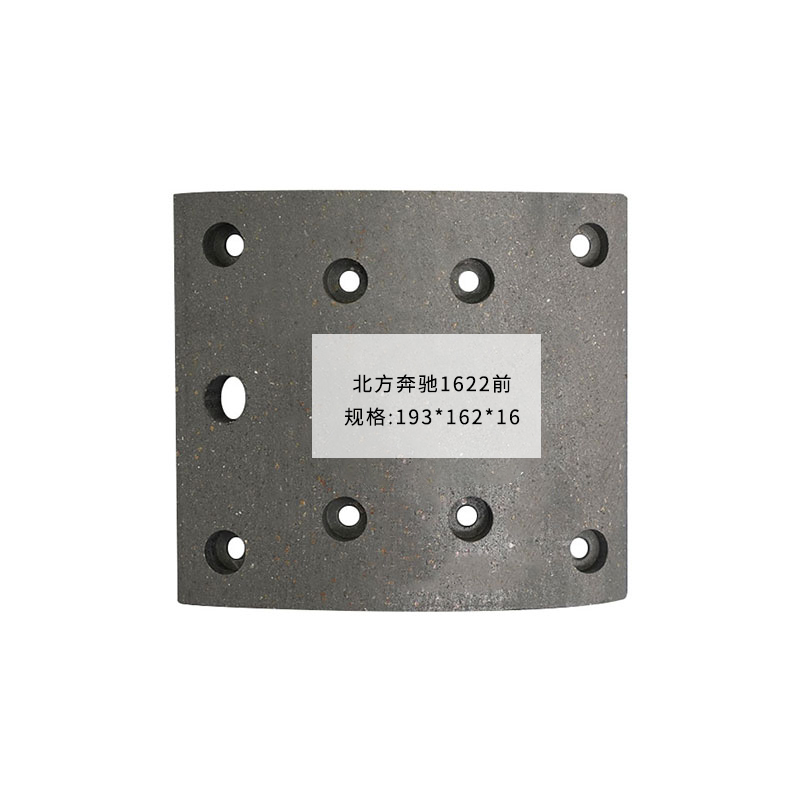

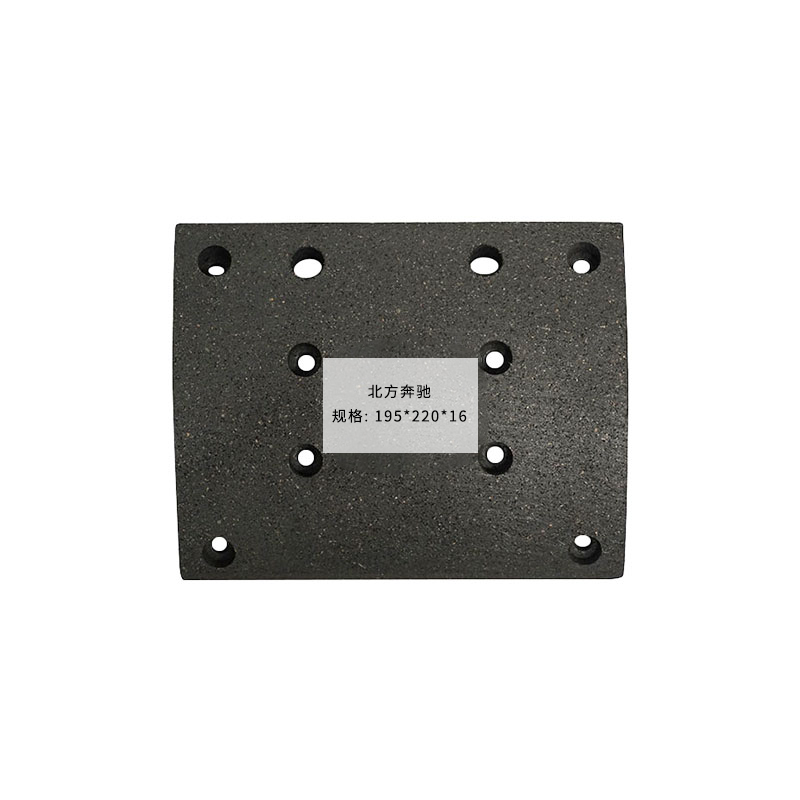

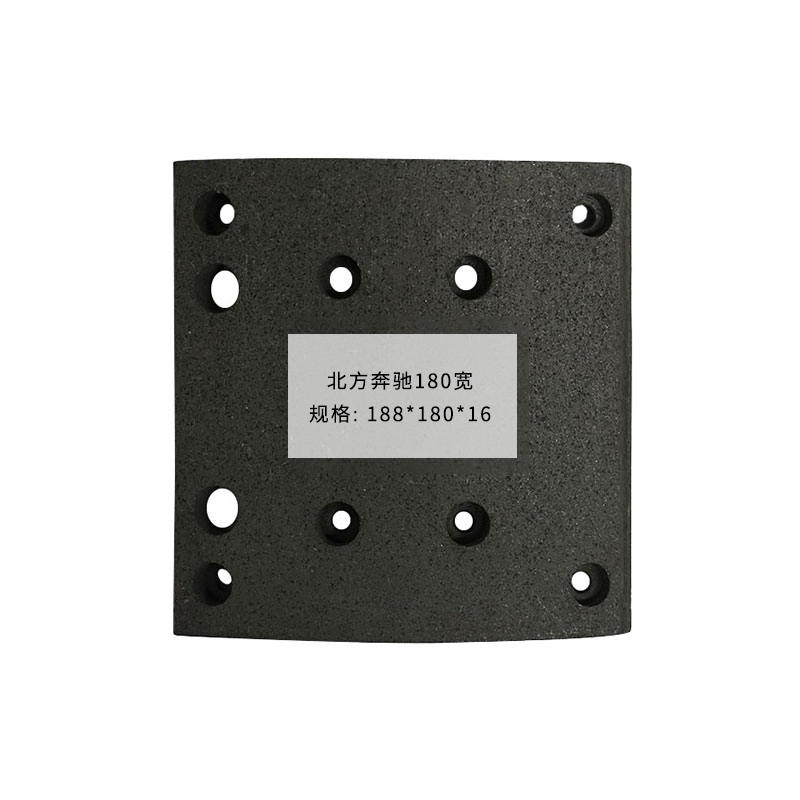

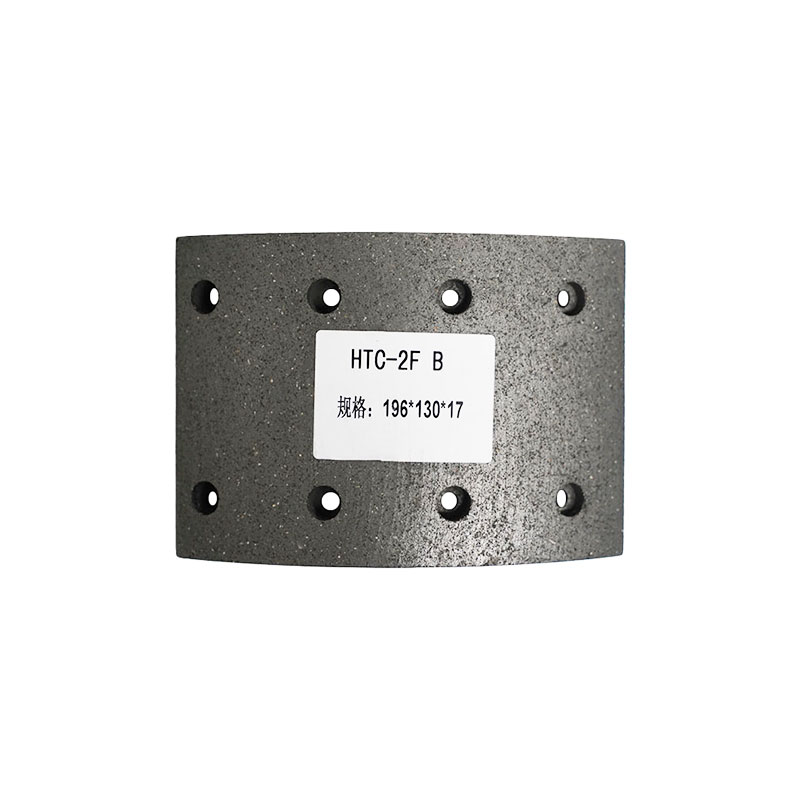

Types of Brake Lining Applications

Brake linings are used in a variety of braking systems across different vehicles. The main applications include:

- Passenger cars: Emphasis on quiet operation, low dust, and smooth braking.

- Commercial trucks: Focus on durability and heat resistance for heavy loads.

- Motorcycles and scooters: Require compact linings with high friction performance.

- Industrial machinery: Customized linings for specific machinery operating under extreme conditions.

Maintenance and Replacement of Brake Linings

Regular inspection and maintenance of brake linings are essential for vehicle safety. Key points to consider include:

- Visual inspection for cracks, glazing, or uneven wear.

- Checking thickness regularly; most manufacturers recommend replacement when lining thickness falls below 3mm.

- Listening for unusual noises indicating worn linings or rotor issues.

- Professional servicing to ensure proper installation and braking performance.

Comparing Brake Lining Materials

The choice of brake lining material significantly affects vehicle performance. The table below provides a clear comparison:

| Material | Durability | Noise Level | Heat Resistance | Dust Emission |

| NAO | Medium | Low | Medium | Low |

| Semi-Metallic | High | Medium | High | Medium |

| Ceramic | High | Very Low | Medium | Very Low |

Future Trends in Brake Lining Technology

The brake lining industry is evolving to meet stricter environmental and performance standards. Emerging trends include:

- Eco-friendly linings using organic or biodegradable materials.

- Advanced composites for enhanced wear resistance and reduced weight.

- Smart linings with embedded sensors to monitor wear and optimize maintenance schedules.

- Integration with regenerative braking systems in electric vehicles for improved energy efficiency.

Conclusion

Selecting the right brake lining is crucial for vehicle safety, performance, and longevity. By understanding material types, performance factors, and maintenance practices, drivers and fleet operators can ensure reliable braking under all conditions. As technology advances, brake linings will continue to evolve, offering greater efficiency, safety, and environmental sustainability.

English

English 中文简体

中文简体